Compared with silicon steel core transformers of the same capacity and voltage level, amorphous ribbon core reduces no-load loss by 70% and no-load current by about 75%. Energy saving effect is obvious, so it is more popular among users and gradually widely used.

We can adjust the configuration of the whole core production line from cutting, material handling, bundling, testing, annealing and other processes according to the customer's demand for different cores, and customize the solution for the customer.

Different types of enterprises have amorphous different priorities for core cutting line solutions, for example, some like high output rate, some need flexibility, while some better focus on affordability.

In addition, some companies need to prioritize low burr cutting and minimal waste, especially for thin and light amorphous alloys; for others, the maximum cut length to be processed is an issue; for others, the lamination width may be a consideration.

Therefore, when providing a complete line solution for cores, we focus on the customer's needs and then weighs the pros and cons of each aspect to configure an amorphous core cutting line that meets the customer's specific requirements. In many cases, customers have found that the solutions provided by us not only met their current needs, but exceeded their expectations.

When you need solutions for the cutting of amorphous ribbon cores, we can provide one-stop services, with a focus on the following aspects:

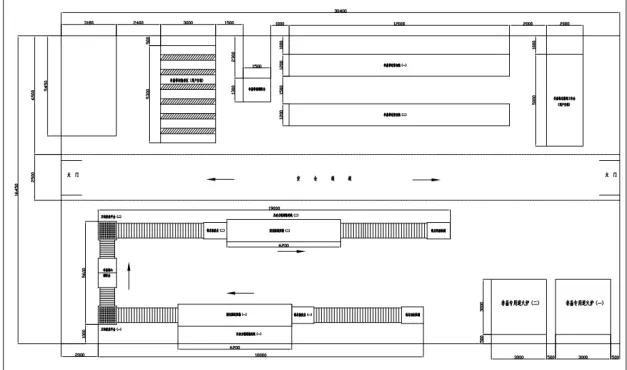

We can configure the transformer core cutting machine to meet customer requirements of amorphous ribbon core production. Besides, we also offer auxiliary equipment such as core stacking table, 90 degree tilt table, annealing furnace, three-decoiler feeding system, tunnel ovens, and more to adapt the actual production needs. Below is the layout diagram of the amorphous ribbon core equipment designed by our company for global customers.

Our automatic core cutting machine is technologically advanced and of top-notch quality. Following ISO9001 quality management system requirements, we strictly adhere to standard management system operations. We implement comprehensive and full-process strict quality control at all stages of product involvement to ensure that we provide first-class production equipment to our customers, ensuring that the amorphous ribbon cores produced by our customers meet high-quality standards, including dimension and magnetic performance testing.

If you are interested in solutions for amorphous ribbon core cutting machines, we recommend that you contact us directly to obtain detailed information and customized solutions.

We offer transformer core production equipment designed for the production of amorphous cores. The primary processes include cutting, annealing, drying, tilting (overturning), testing, and more.

In addition to manufacture and supply transformer core production equipment, we are also a reliable partner for transformer manufacturers and companies for manufacturing transformer cores and core laminations to develop core production solutions that are comprehensive to satisfy the requirements of specifications and demands.